Fully 3D Printed Bionic Robotic Hand with 24 DoF and Advanced Control

The Fully 3D Printed Bionic Robotic Hand project centers on the innovative design, manufacturing, and application of a highly articulated robotic hand. Featuring 24 Degrees of Freedom (DoF) and advanced force or position control systems, this bionic hand aims to replicate the dexterity and functionality of a natural human hand. Showcased at a Veterans' event, the project successfully conducted live trials with amputee veterans, garnering invaluable feedback that inspired the development of an enhanced V2 prototype.

Fully 3D Printed Bionic Robotic Hand

Project Overview

The Fully 3D Printed Bionic Robotic Hand project represents a groundbreaking initiative in the field of prosthetic technology, focusing on the innovative design, manufacturing, and application of a highly articulated robotic hand. Featuring an impressive 24 Degrees of Freedom (DoF) and advanced force and position control systems, this bionic hand aspires to replicate the dexterity and functionality of a natural human hand. By leveraging cutting-edge 3D printing techniques, the project not only enhances the mechanical precision and customization of the prosthetic but also significantly reduces production costs and time. The project was prominently showcased at a Veterans' event, where live trials with amputee veterans were conducted, providing invaluable feedback that has driven the development of an enhanced V2 prototype. This initiative underscores the potential of integrating advanced manufacturing technologies with user-centered design to deliver highly functional and adaptable prosthetic solutions.

Objectives

The primary objectives of the Fully 3D Printed Bionic Robotic Hand project were to:

Innovative Design and Articulation: Develop a robotic hand with 24 Degrees of Freedom to closely mimic the range of motion and functionality of a natural human hand.

Advanced Control Systems: Implement sophisticated force and position control mechanisms to ensure precise and responsive movements.

3D Printing Integration: Utilize state-of-the-art 3D printing technologies to enable rapid prototyping, customization, and efficient manufacturing processes.

User-Centric Development: Engage with amputee veterans through live trials to gather feedback and insights, ensuring the prosthetic meets the practical needs and preferences of its users.

Cost and Time Efficiency: Reduce the overall cost and production time of the prosthetic hand without compromising on quality or functionality.

Continuous Improvement: Use feedback from initial trials to inform the development of an enhanced V2 prototype, incorporating improvements based on real-world user experiences.

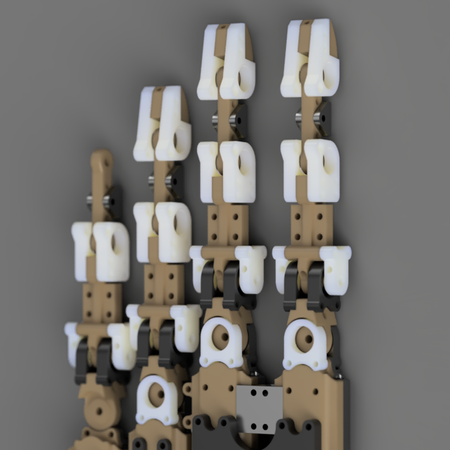

Design and Development

Mechanical Design and Articulation: The bionic hand was meticulously designed to incorporate 24 Degrees of Freedom, allowing for a wide range of movements that emulate the complexity of a natural human hand. Each finger joint and the wrist were engineered to provide independent and coordinated motion, enabling tasks such as gripping, pinching, and precise manipulation of objects. The mechanical structure was optimized for durability and lightweight performance, ensuring that the prosthetic is both robust and comfortable for extended use.

Advanced Control Systems: To achieve seamless and intuitive control, the robotic hand was equipped with advanced force and position control systems. These systems utilize a combination of sensors and actuators to monitor and adjust the hand's movements in real-time. Force sensors detect the amount of pressure applied, allowing for delicate handling of fragile objects, while position sensors ensure accurate placement and movement of each joint. The integration of these control systems enables the hand to perform complex tasks with high precision and responsiveness.

3D Printing and Manufacturing: The project leveraged the capabilities of 3D printing to facilitate rapid prototyping and customization. High-resolution 3D printers were used to fabricate intricate components with fine details, ensuring that each part fits together seamlessly. The use of 3D printing not only accelerated the development process but also allowed for the easy modification and iteration of designs based on user feedback. Additionally, the manufacturing process was optimized to reduce material waste and production costs, making the prosthetic more accessible to a broader range of users.

User-Centric Development and Testing: A critical aspect of the project was engaging with amputee veterans through live trials conducted at a Veterans' event. These trials provided an opportunity for real-world testing of the bionic hand, allowing users to interact with the prosthetic in various scenarios. Feedback gathered from these sessions was instrumental in identifying areas for improvement, such as enhancing grip strength, refining movement algorithms, and improving overall comfort and usability.

Prototyping and Iteration: Based on the insights gained from user trials, the project team embarked on the development of an enhanced V2 prototype. This iteration focused on incorporating user feedback to address identified shortcomings and enhance the overall functionality and user experience of the prosthetic hand. Key improvements included more ergonomic design elements, enhanced sensor accuracy, and refined control algorithms to provide smoother and more natural movements.

Challenges and Solutions

1. Achieving High Degrees of Freedom: Challenge: Designing a prosthetic hand with 24 Degrees of Freedom posed significant mechanical and control complexities. Solution: The project team employed modular design principles, breaking down the hand into smaller, manageable components. Advanced CAD software was used to simulate and optimize joint movements, ensuring seamless integration of multiple DoFs. Additionally, robust control algorithms were developed to manage the intricate coordination between joints.

2. Integration of Advanced Control Systems: Challenge: Ensuring precise and responsive control over multiple joints required sophisticated sensor and actuator integration. Solution: High-precision sensors and actuators were selected and integrated into the design. Custom firmware was developed to process sensor data in real-time and adjust actuator outputs accordingly. Extensive testing and calibration were conducted to fine-tune the control systems, achieving the desired level of responsiveness and accuracy.

3. Balancing Durability and Lightweight Design: Challenge: Creating a prosthetic hand that is both durable and lightweight is essential for user comfort and longevity. Solution: The team utilized advanced materials, such as lightweight polymers and reinforced composites, to achieve the necessary strength without adding excessive weight. Structural analysis and finite element modeling were employed to optimize the design for durability while maintaining a minimal weight profile.

4. Customization and Fit: Challenge: Ensuring that the prosthetic hand fits comfortably and accommodates the unique anatomical variations of each user. Solution: 3D scanning and printing technologies were used to create custom-fit components tailored to each user's residual limb. Adjustable mounting systems were incorporated to allow for fine-tuning of the fit, enhancing comfort and usability.

5. User Feedback and Iterative Improvement: Challenge: Incorporating diverse user feedback into the design and development process required a flexible and responsive approach. Solution: The project adopted an iterative development cycle, where user feedback was systematically collected, analyzed, and implemented into subsequent design iterations. Agile project management methodologies facilitated rapid prototyping and continuous improvement based on real-world user experiences.

Outcomes and Impact

The Fully 3D Printed Bionic Robotic Hand project achieved several significant outcomes that demonstrate its impact and potential:

Enhanced Dexterity and Functionality: The 24 DoF design successfully replicates the intricate movements of a natural human hand, enabling users to perform a wide range of tasks with high precision and ease.

User Validation: Live trials with amputee veterans validated the prosthetic's functionality and comfort, providing critical insights that informed the development of the V2 prototype.

Cost and Time Efficiency: The utilization of 3D printing technologies streamlined the manufacturing process, reducing both production costs and time, thereby making the prosthetic more accessible to those in need.

Customization and Adaptability: The ability to customize the prosthetic hand for individual users enhances user satisfaction and ensures a better fit, contributing to improved quality of life for amputees.

Inspiration for Future Innovations: The project's success has inspired further research and development in the field of prosthetic technology, highlighting the potential of integrating advanced manufacturing techniques with user-centered design.

Positive Community Impact: Showcasing the bionic hand at a Veterans' event fostered a sense of community and provided valuable support to amputee veterans, demonstrating the project's commitment to social responsibility and technological advancement.

Skills Demonstrated

Mechanical Engineering: Expertise in designing complex, multi-DOF mechanical systems with a focus on durability and functionality.

Advanced Control Systems: Proficiency in developing and implementing sophisticated force and position control algorithms for precise robotic movements.

3D Printing and Additive Manufacturing: Skilled in utilizing 3D printing technologies for rapid prototyping, customization, and efficient manufacturing processes.

User-Centered Design: Ability to incorporate user feedback into the design and development process, ensuring that the final product meets the practical needs and preferences of its users.

Prototyping and Iterative Development: Experience in rapid prototyping, testing, and iterative design to refine and enhance product functionality and usability.

Interdisciplinary Collaboration: Demonstrated capability to work across multiple disciplines, including mechanical design, electronics, software development, and user experience, to achieve cohesive project outcomes.

Problem-Solving: Strong analytical and problem-solving skills to address complex engineering challenges and implement effective solutions.

Project Management: Competence in managing complex projects, coordinating between different teams, and ensuring timely and efficient project execution.

Conclusion

The Fully 3D Printed Bionic Robotic Hand project stands as a pioneering achievement in the realm of prosthetic technology, showcasing the successful integration of advanced mechanical design, sophisticated control systems, and innovative manufacturing techniques. By replicating the dexterity and functionality of a natural human hand, this bionic prosthetic offers amputee users enhanced independence and quality of life. The project's emphasis on user-centric development, underscored by live trials with amputee veterans, ensures that the prosthetic meets real-world needs and fosters meaningful user engagement.

The successful development and testing of the V1 prototype, coupled with the invaluable feedback garnered from initial user trials, lay a strong foundation for the enhanced V2 prototype. This iterative approach not only improves the prosthetic's functionality and comfort but also paves the way for future advancements in personalized prosthetic solutions. Moving forward, the Fully 3D Printed Bionic Robotic Hand project exemplifies how technological innovation, when combined with user-focused design and advanced manufacturing, can lead to impactful solutions that significantly enhance human capabilities and well-being.

Project Gallery